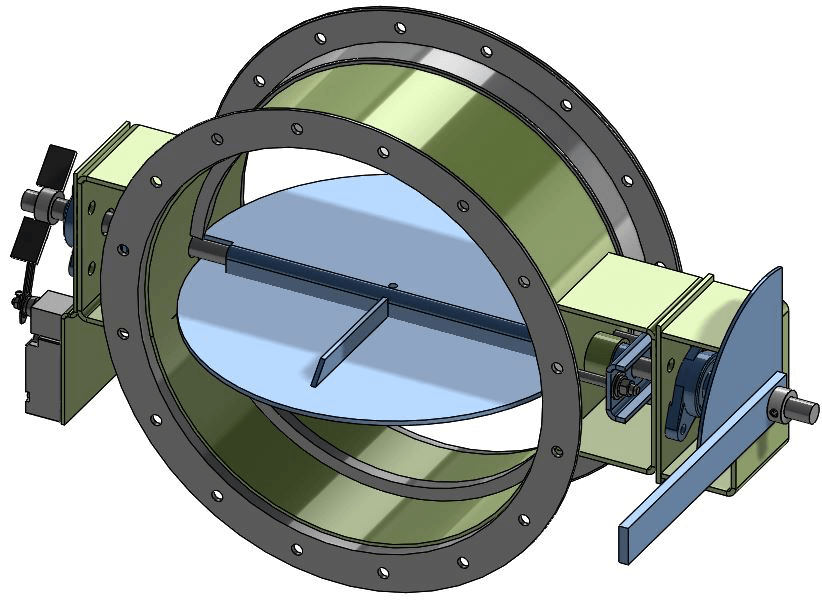

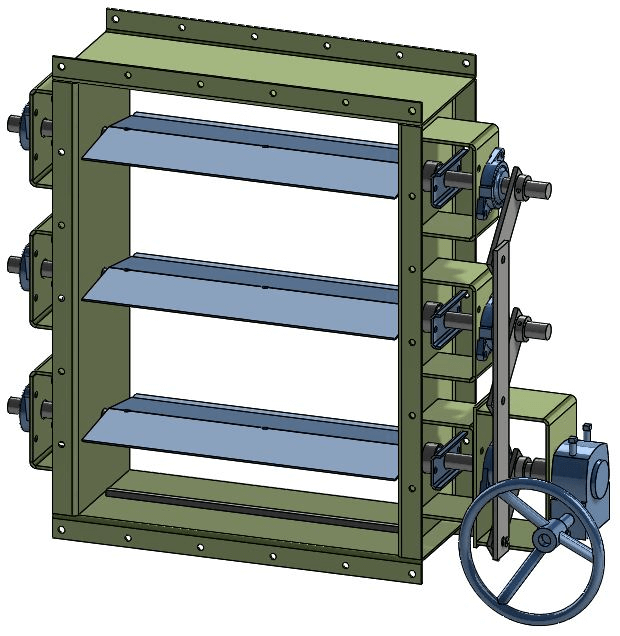

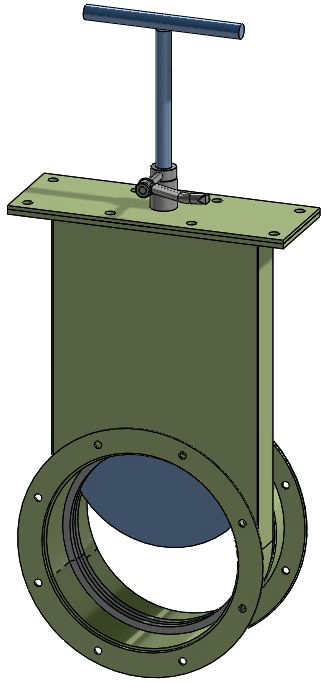

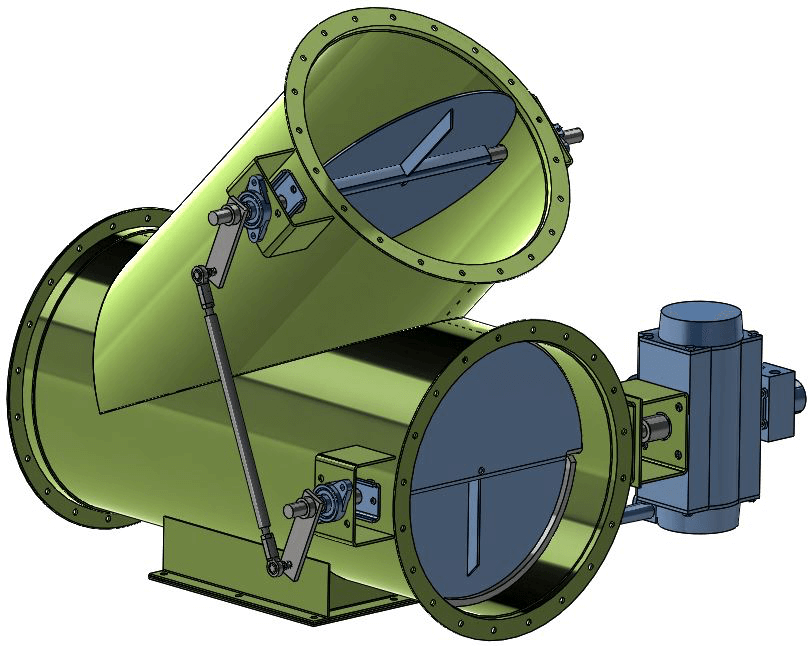

Slide Gate / Guillotine Dampers

From design to fabrication, Kelair's slide gate & guillotine dampers are manufactured with the highest quality materials to the exact specifications of clients.

Download our BrochureKelair Dampers Brochure

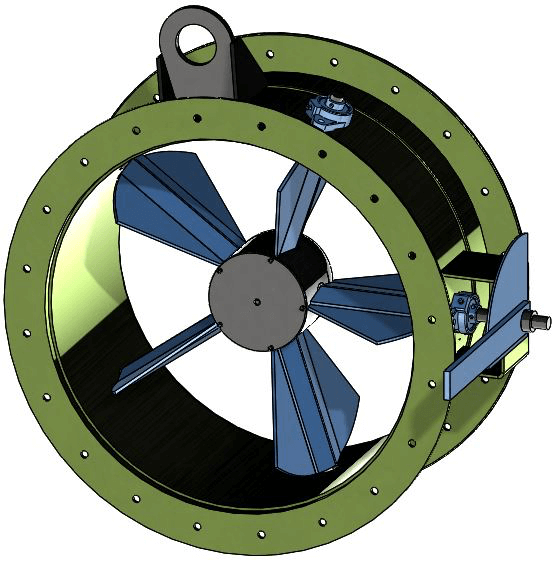

Gate dampers that provide dependable, low leak isolation

Slide gate dampers or guillotine dampers are a type of industrial damper commonly used when one or more of the following are applicable:

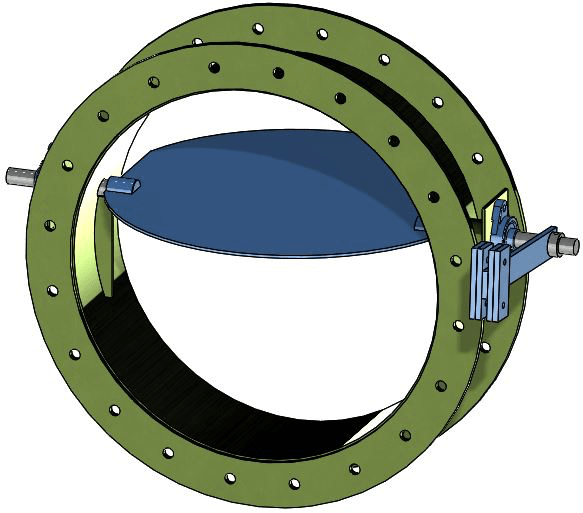

- Minimal spacing (i.e. flange-to-flange) is available on the duct

- The blade is not best suited to stay in the duct while open due to a flow environment laden with abrasive particulate or high acidity

- Minimal maintenance is required

- Low leakage and low-pressure drop are required

They perform best where flow control is not critical but low leakage is. These types of gate dampers are well suited for situations where isolation of an air stream or gas flow occurs frequently due to routine maintenance, inspection or repair. Kelair’s heavy duty construction allows for slide dampers or guillotine dampers to function reliably in demanding environments with corrosive gas, particulates, and high temperature.

Kelair’s slide gate dampers provide numerous benefits to your application. They cut through heavy particulates with smooth opening and closing. They have fewer moving parts, therefore less maintenance. If space is an issue, guillotine dampers require less of it along the duct (flange to flange). Overall, slide gate or guillotine duct dampers benefit the customer with solid, long term operational savings.

*Operational testing and calibrating are completed at the factory prior to installation.

Product Features & Specifications

- Sizes: from 10″ to 120″

- Process Temperature: up to 1000° F

- Configurations: round, square, & rectangular

- Construction: S.S. or painted C.S. (others available upon request)

- Shutoff: up to 99%

- Seal Options: compression & metal seat

- Actuation: manual, electric & pneumatic (spring return and failsafe available)

- Modulation: open/closed

- Pressure: up to 1 PSI & 4000 FPM process air (higher available upon request)

- Enclosed bonnet (blade retraction) area standard