Kelair Products

Dampers that are built beyond industrial-grade standards

All Kelair Dampers are Engineered and Manufactured to our Customer's Specifications

Whether it is an order for a single louver damper or 80 butterfly dampers our collaboration with our Manufacturer’s Reps and their clients is the same. We pride ourselves on the longevity of the relationships we have with our Reps and customers and strive to make their experience as seamless and effortless as possible.

Selecting the best damper for an application is important to ensure the highest gas or airflow efficiency. At Kelair Products, Inc., we strive to maximize this flow efficiency while minimizing our customers’ cost. We have found that no single standard design is suitable for all environments and/or applications. That is why we manufacture so many different types of industrial dampers and special options. We work carefully with our customers and reps to choose the best combination of our field proven features and configurations to provide the most reliable and economical solution to their air and gas flow requirements.

Kelair industrial dampers are designed for use in: incineration systems, pollution control, thermal oxidizers, regenerative thermal oxidizers, dust collectors, turbine exhaust, heat recovery and many other process air and gas systems. We work with our customers to engineer Kelair dampers to their exact specifications and requirements. We are expert at engineering and manufacturing complex, heavy duty industrial dampers specializing in custom designs for unusual or severe duty conditions. We are equally proficient at producing simple butterfly industrial dampers, whether they ship one at a time or over a hundred in an order.

Dampers Manufactured by Kelair Products

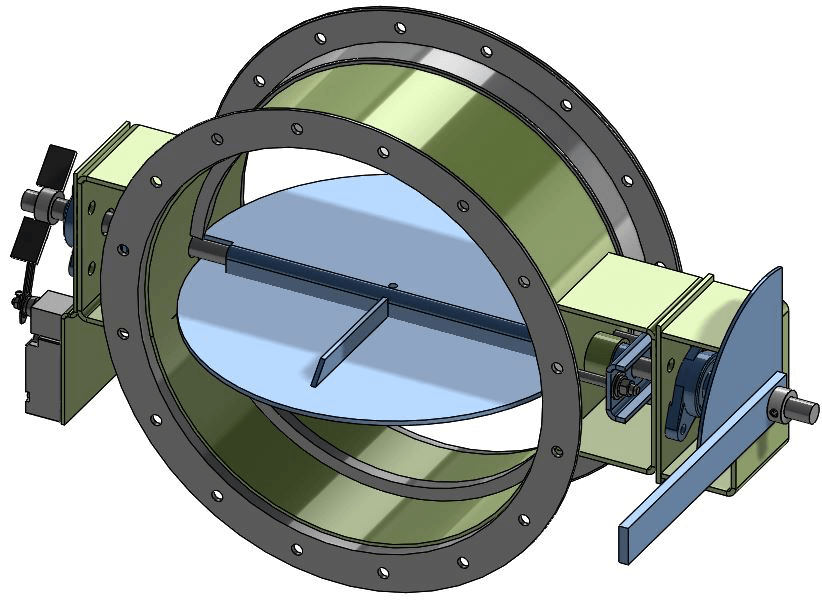

Butterfly Dampers

Butterfly dampers used by Kelair have the simplest design and the fastest turnaround. They are the economical choice for applications ranging from light duty to heavy duty and low temperature to high temperature.

Industrial Ducting

Kelair's custom-designed industrial ductwork is used in various applications, including pneumatic conveying, air pollution control, and industrial ventilation systems.

Isolation Valves

Isolation valves are typically placed at specific points throughout a pipeline or system. Among the most common spots for isolation valves to be installed include places where pipes branch off in multiple directions or at junctions.

Butterfly Valves

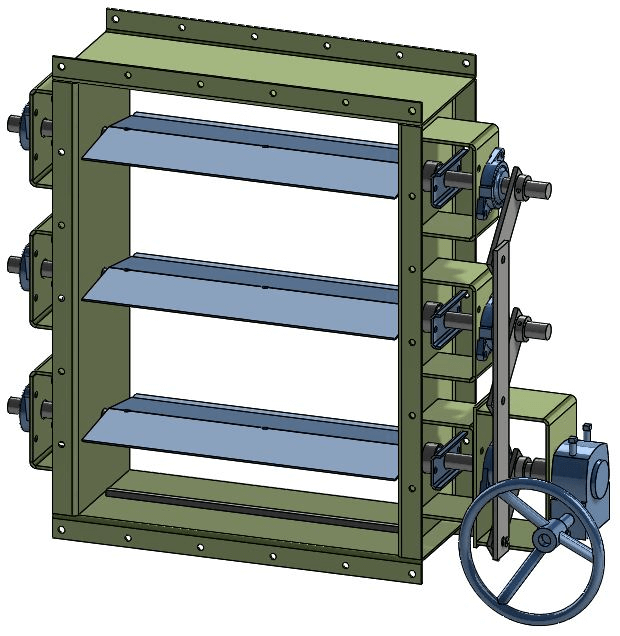

Louver Dampers

Kelair's Louver Dampers are applicable for both light, and heavy-duty industrial ventilation for high volume flow control, and isolation applications. This damper modulates the flow of air and gas in dry or wet conditions or can shut them off altogether.

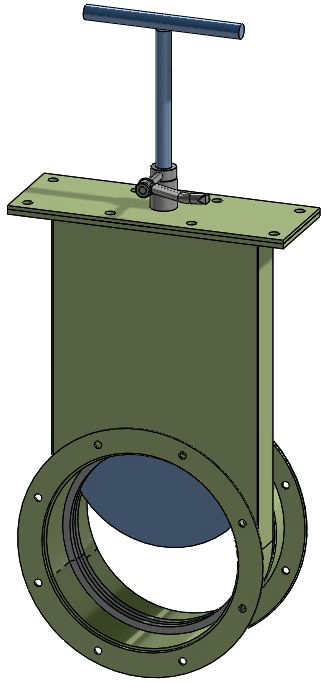

Slide Gate / Guillotine Dampers

These types of slide gate or guillotine dampers are used primarily as shut off devices. Kelair's rugged, heavy duty designs are available round or square with sizes from 4" up to 96" making them an ideal solution for industrial applications.

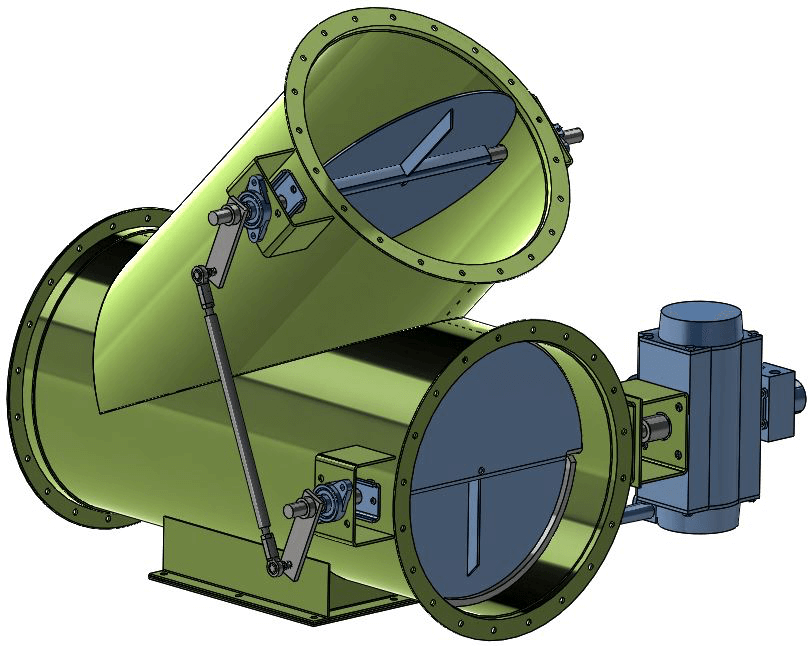

Diverter & Tee Dampers

Diverter Dampers or Tee Dampers are used to redirect air stream from one outlet to another. These types of dampers are widely used in incineration systems to divert process air and gas to the incinerator or by-pass to the atmosphere.

Refractory Dampers

Kelair’s Refractory dampers are manufactured to withstand temperatures up to 2100 F in corrosive, particulate and/or process gas environments. This unique design helps reduce heat loss and provide erosion protection for the frame.

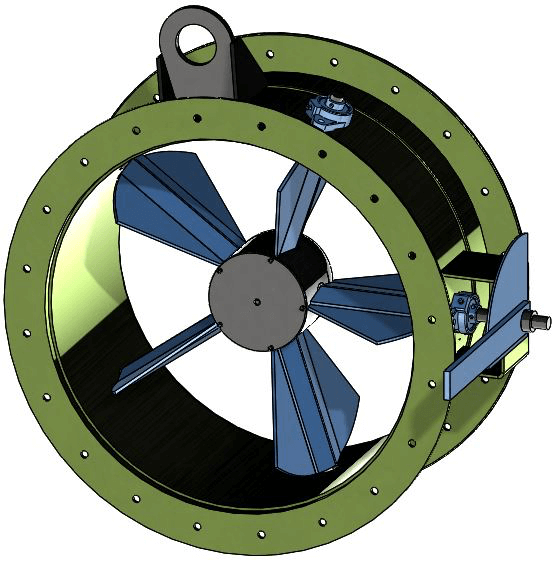

Inlet Vane Dampers

Inlet Vane Dampers work with fans and blowers to enhance their performance by controlling air volume and fan shut-off. Kelair’s design boasts no external linkage, eliminating pinch points and damage to the assembly.

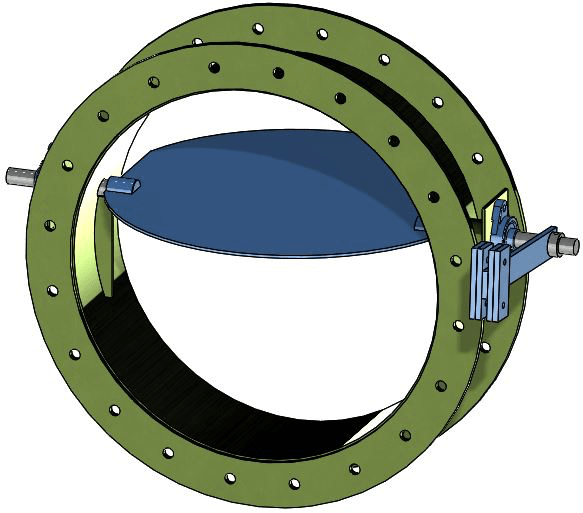

Backdraft Dampers

Kelair’s Backdraft dampers are engineered to allow airflow in one direction and prevent reverse airflow. Backdraft dampers control airflow in ventilation systems either to modulate or to shut off moving air through a fan opening when it is turned off.

Stack Cap Dampers

Kelair's Stack Cap Dampers isolate the stack opening to prevent foreign material from entering and conserve warmth when the stack is shut down. The dampers deliver accurate airflow and isolation at high temperatures, reducing the stack effect.