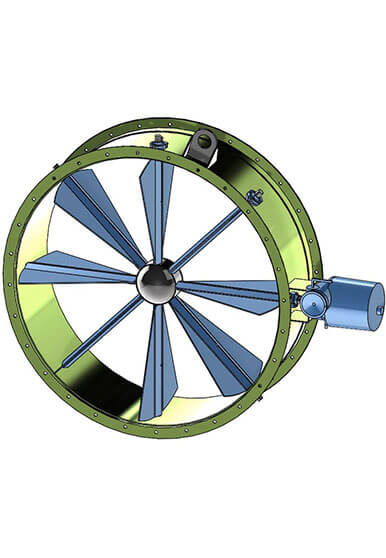

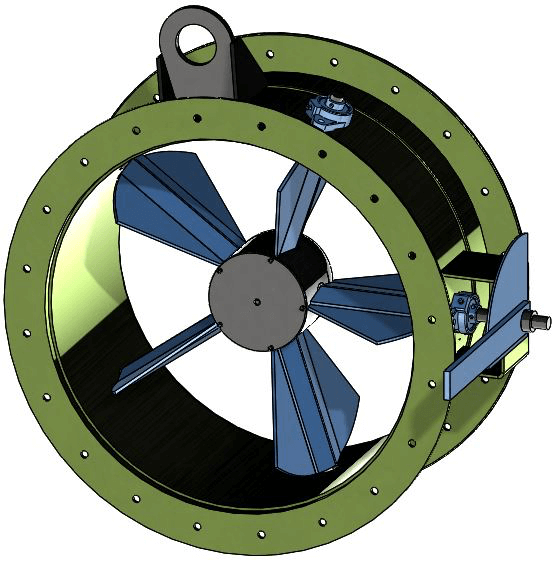

Inlet Vane Dampers

Kelair’s Inlet Vane Dampers work with fans and blowers to enhance their performance by controlling air volume and fan shut-off.

Download our BrochureKelair Dampers Brochure

Engineered for Easy Maintenance and Service

The Inlet Vane Damper is an ideal way to improve performance and efficiency within industrial applications. Vane dampers (also known as Variable Inlet Vane Dampers (VIV), Inlet Vane Control Dampers (IVC), Radial Vane Dampers, Inlet Valve Dampers and Vortex Dampers among others) perform the same basic function: they pre-spin air, in the same direction as the fan rotation, before it enters the fan inlet. This directed air reduces the load on the fan by lowering the fan pressure.

Kelair’s Inlet Vane Dampers provide an effective way to reduce energy consumption by regulating airflow, which directly lowers operational costs. This reduction in energy use leads to a faster return on investment, making them a cost-effective solution for industrial applications. Over time, these savings add up, improving the overall efficiency and sustainability of a facility’s ventilation system.

Kelair’s Inlet Vane dampers have a central hub surrounded by multiple blades and are used primarily in clean air/gas environments without particulates. They are appropriate for both volume control and fan shutoff. This damper has the added benefit of easily allowing field changeable air pre-spin rotation.

Kelair’s dampers are specifically engineered with ease of maintenance in mind, ensuring minimal downtime and streamlined servicing. Their design allows for quick inspections and adjustments without requiring extensive disassembly, making them a reliable choice for long-term operation. By minimizing maintenance-related interruptions, these dampers enhance efficiency and reduce labor costs.

*Operational testing and calibrating are completed at the factory prior to installation.

Product Specifications & Features

- Sizes: 12″ to 96″

- Process Temperature: up to 1100° F

- Configurations: round

- Construction: stainless steel or carbon steel (other materials available upon request)

- Shutoff: up to 90%

- Actuation: manual, electric, & pneumatic (failsafe available)

- Modulation: open/close or modulating

- Pressure: up to 1 PSI & 4000 FPM process air (higher available upon request)

Interested in improving your facility’s energy efficiency? Kelair’s Inlet Vane Dampers provide a reliable solution for reducing energy costs and enhancing system performance. Contact us today to learn more about how our dampers can benefit your operations or request a customized quote to find the perfect fit for your needs.

Frequently Asked Questions

- What are examples of typical inlet vane damper applications?

- What does proper care look like for an inlet vane damper?

- What is the minimum information I need to get a quote on a damper?